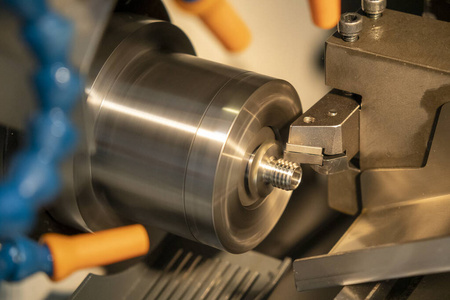

CNC machining, utilizing advanced CNC machining tools, offers distinct advantages such as stable machining quality, high accuracy, repetition precision, and efficiency. To meet the design accuracy requirements of parts, a systematic approach to CNC machining processes is essential. This article explores the principles and methods for dividing CNC machining processes and arranging their sequences.

How To Divide CNC Machining Processes

Process planning encompasses the entire machining process, requiring careful consideration of factors such as part structure, machine tool capabilities, and CNC machining content. The division of CNC machining processes can be approached through the following methods:

1. Centralized Tool Sorting Method

Divide processes based on the tools used, aiming to utilize the same tool CNC for processing all applicable parts. This minimizes tool changes, reduces idle time, and mitigates positioning errors.

2. Sorting Method of Processing Parts

For parts with extensive CNC processing, divide them based on structural characteristics such as internal shape, outer shape, or specific surfaces. Prioritize processing planes and locating surfaces, followed by holes, simple geometric shapes, and then complex shapes.

3. Rough and Fine Machining Sequence Method

Apply a sequence method for parts prone to deformation, involving separate rough and fine CNC machining. Calibration after rough machining addresses potential deformations, ensuring precision.

Principles For The Sequence Arrangement Of CNC Machining Processes

1. Principle of Rough Before Fine

Sequentially progress through rough machining, semi-finish machining, and finish machining to gradually enhance precision and surface quality. Consider allowing a resting period between rough and finish machining for stress release, particularly beneficial for parts with high accuracy requirements.

2. Principle of Machining Datum Plane First

Initiate machining with the surface designated as the finishing reference, ensuring accuracy and minimizing clamping errors. Follow a sequence based on datum conversion and gradual improvement of machining accuracy.

3. Principle of Face Before Hole

Prioritize processing flat surfaces before holes, especially for parts like boxes and brackets. This approach provides a stable reference for subsequent operations and facilitates accurate hole processing.

4. Principle of Inside Before Outside

For precision sleeves, process the hole before the outer circle, ensuring high coaxiality. This simplifies fixture structures and meets stringent requirements for outer circle and hole alignment.

5. Principle of Reducing Tool Change Times

Arrange machining sequences based on the tool entering the machining position to minimize tool changes and enhance overall efficiency.

In conclusion, adhering to these principles and methods ensures a systematic and efficient approach to CNC machining processes, meeting the design accuracy and quality requirements of machined parts.